Precision Swiss Micro Machining

Blueacre Technology offers precision Swiss CNC machining to produce complex machined components. Swiss CNC enables high accuracy and precision machining of very small features. Blueacre Technology’s Swiss CNC equipment is capable of highly precise milling, tapping, turning, boring and drilling.

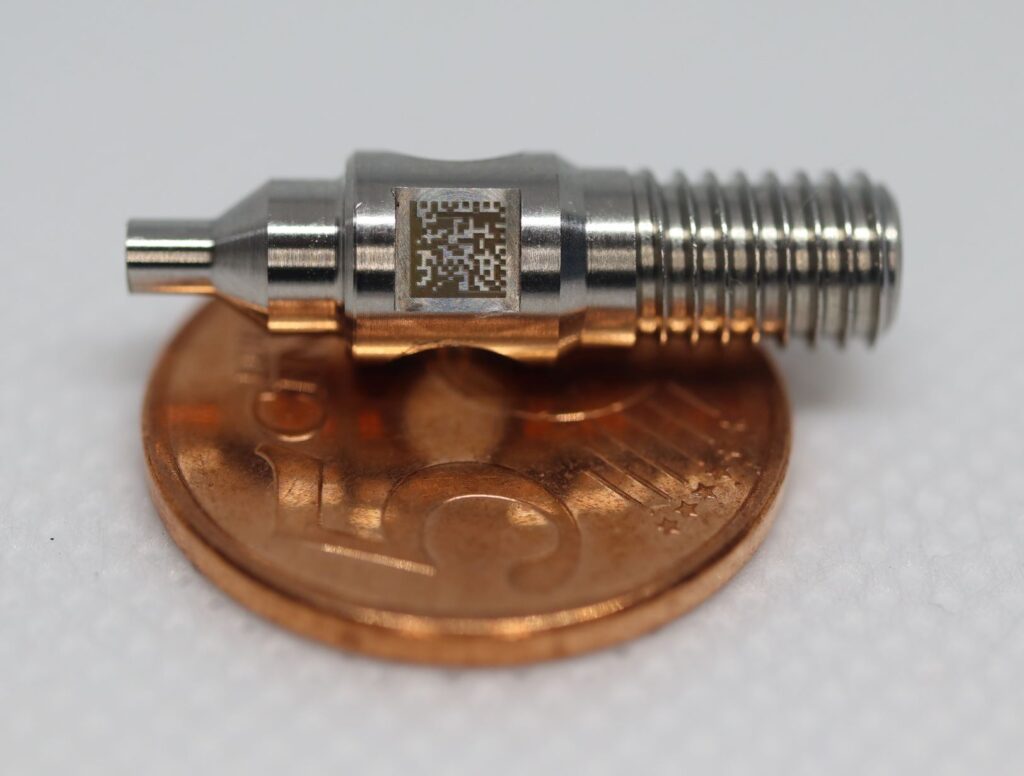

Swiss CNC can be used to manufacture a wide range of components such as medical screws, micro gears, micro nozzles, long slender pins, laparoscopic and other medical device components, implants, aerospace components and electronic contacts for connectors. Blueacre Technology’s expertise in laser mark adds high levels of traceability to high value parts.

For the highest levels of precision on the widest range of materials, with the tightest levels of tolerance and high repeatability, the solution is Blueacre Technology Swiss CNC machining.