Description

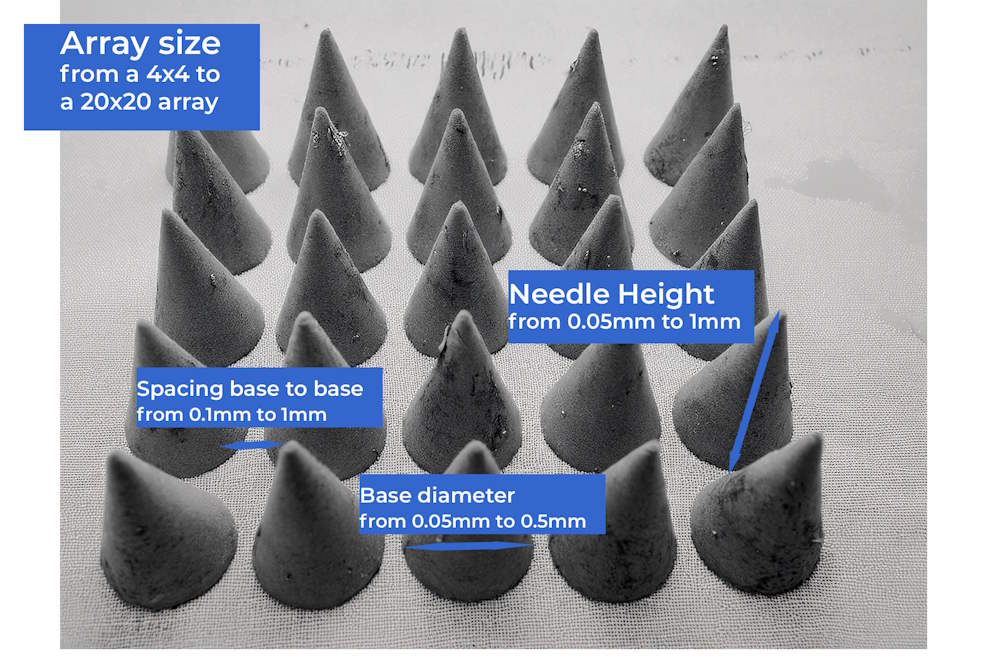

Non standard conical molds are infinitely customizable to your needs. Lead time for customized molds is 1-2 weeks. Molds can be customised according to the following criteria:

- Needle height: from 0.05mm to 1mm

- Spacing base to base: from 0.1mm to 1mm

- Base diameter: from 0.05mm to 0.5mm

- Array size: from a 4×4 to a 20×20 array

- Tip size less than 5um

Blueacre Technology utilise laser fabrication technology to produce fully customizable microneedle molds in PDMS (silicone). The molds can be used to manufacture microneedle arrays from a range of bio-degradable materials. The laser process is a non-contact sterile and industrially scalable process, capable of machining microneedles in a range of shapes and sizes.

Molds produced by Blueacre Technology are continually been used by research organisations around the globe in a range of scientific studies and produce some of the most durable and sharp microneedle arrays that can be fabricated.